Cell culturing under flow conditions

Organ-on-a-chip (OoC) applications, which were created by combining labs on chips and cell biology, are attracting growing interest from scientists and the life sciences industry. An organ is a group of tissues with similar functions. With the use of traditional static cell culturing, it is often impossible to reproduce the exact organ tissue. The surrounding environment of a tissue plays an important role in cell growth and differentiation. Adding flow conditions helps to mimic the in vivo situation more accurately.

Improved in vitro tissues and explants offer large potential in personal medicine by enabling tests of the effect of medicines on actual patient material. Besides, they offer reliable models for drug development tests. Because of the greater accessibility of in vitro tissue, more and better tests can be performed throughout the development course, which helps to detect faults earlier on in the cycle. Improved in vitro models also help to reduce the need for animal testing, an important goal in for instance the cosmetics industry.

Adding flow to cell culturing

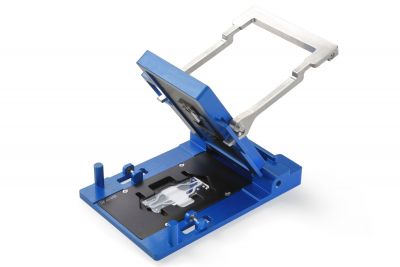

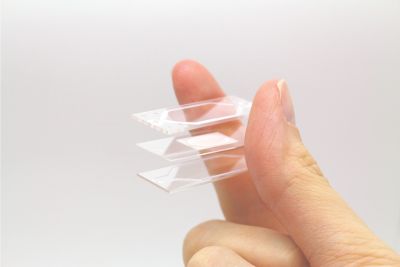

Micronit has developed a general OoC platform which adds flow conditions to static cell culturing. This platform consists of two resealable glass slides with a porous membrane in between, on which the actual cell culturing takes place. Because most users will have experience with cell culturing, we have selected the same membrane materials as used for cell culture inserts, typically porous PET or PC membranes, and attached them on a carrier layer just like a cell culture insert. This cell culturing membrane, in fact the heart of the process, is available in several varieties, with differences in membrane thickness, pore size and pore density.

OoC platform

By combining the membrane layer with the glass top and bottom layers, a closed cell culturing platform with two separate flow chambers on either side of the cell culturing membrane is created. This allows two different flows, of liquids or gases, above and below. The flow is driven by an external supply system. With these two flows, a natural growth environment is simulated. The liquids or gases can contain all the substances the cells need, like nutrients. This way, the cultivation process takes place in a very precise and controlled manner and all biologically relevant data can be accurately tracked.

Considering the importance of the flow quality in these systems, we have focused on highly accurate flow control, instead of the more price focused gravity-based flow concepts. We also have chosen to use non-permeable rigid materials, in which the oxygen level is fully controlled by the medium. This opposed to PDMS-based systems, that are supposed to allow oxygen permeation, but in reality show questionable control and stability of this permeation. The materials used in our system also do not absorb active ingredients, which can be an issue with PDMS due to its molecular structure.

As the top and bottom slides are resealable, our OoC platforms allows full access to the bio-content at any time to perform relevant actions like pipetting and visual inspection. One of the complicating factors in developing culture protocols under flow conditions is cell adhesion. It is not easy to prevent wash-away of cells when direct flow is applied. Our resealable approach allows traditional cell adhesion prior to the addition of flow.

Research and screening

The OoC devices developed and produced by Micronit offer scientists and researchers an accessible way to make use of OoC technology. In particular we serve researchers active in the fields of advanced biomedical engineering, bioMEMS, microfabrication and microelectronics. The devices are used for both research and screening. Our OoC product range consists of devices that can be supplemented with single or multiple chip holders and pumps.

Why choose Micronit’s OoC devices? Let’s sum it up!

- Flexible, not focused on a specific organ model. Our platform can be customized for specific needs.

- Based on established cell culture membranes.

- Fully controllable situation.

- Access to flow chamber and bio content whenever needed.

Specific needs

Are you looking for a specific cell culturing device, that exactly fits your type of research? Micronit is involved in several organ-on-a-chip research and customer projects. Our multidisciplinary team has the expertise to offer integrated solutions for specific customer needs. This has led to valuable collaborations and partnerships - Micronit’s devices are already being used in several research labs around the world to create valuable artificial models (including the gut and lungs) in the field. Contact us for more information!