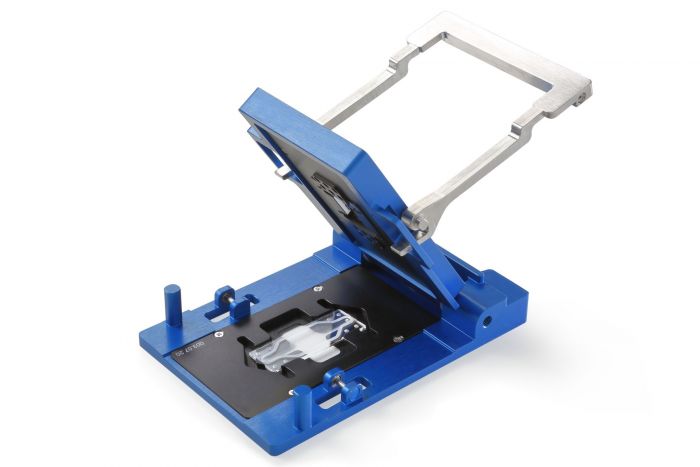

Fluidic Connect Pro chip holder - topconnect - for organ-on-a-chip (OOC)

SKU

11000750

Availability:

In stock

€2,025.00

per Kit

Easy interfacing for OOC chips.

Fluidic Connect Pro chip holder for organ-on-a-chip (OOC). Ready to use all Micronit OOC chips. The Load 'n' Seal design ensures tight connections without breaking your chips. Together with the Fluidic Connect Pro Connection kit, that contains the tubing and the perfluoroelastomer ferrules, you have the best solution for all the organ-on-a-chip devices in the webstore.

Note: Never use ferrules from a different supplier this will cause leakage or can damage the chip.

Features and Benefits:

- Fast, easy and robust fluidic connections

- Future proof, thanks to replaceable inserts

- Durable design

- Smart sealing solutions to prevent chip cracking

- Large chip view area possible

- Compatible with upright and inverted microscopes

Kit contents

- Casing

- Fluidic Connect Pro Frame

- Top insert (premounted)

- Bottom insert (premounted)

- Spare screws

- Screwdriver

- USB stick

- Instruction Manual

| Unit of measurement | Kit |

|---|---|

| Holder concept | Fluidic Connect Pro |

| Holder sub-type | Organ On Chip - Single slot |

Customer Questions

Can I use a ferrule from a alternative supplier, like for instance IDEX is offering, in combination with the Fluidic Connect Pro?

This will NOT work and will cause damage to the chip or holder. Our ferrules for use with the Fluidic Connect Pro are a Micronit proprietary design and also a specific grade of FFKM is used.

I have a Elveflow OB1 pressure based pump what connectors do I need?

Nuts and ferrule

Elveflow uses 1/4-28 screw in connections on there reservoirs and sensors. To interface you will need Flangeless nuts 1/4-28 for 1/16" tubing, including compatible ferrules. Those nuts and ferrules are included in Elveflows "Kit Fittings Starter Pack Push-in".

This item wil look like this:

In addition you will need our connection kit. Our Connection kit includes nuts or ferrules specificilly designed for our Fluidic Connect Pro, Fluidic Connect 4515 or side connect holders. Tubing included in "Kit Fittings Starter Pack Push-in"

The 1/16"OD PTFE tubing included in the kit has a very large ID (1/32" ~0.79mm) and is from a relatively soft material, this is not so suitable for bot our Fluidic Connect Pro and Fluidic Connect 4515 holders as there's very limited wall thickness. We recommend alternative tubing, like ETFE with a maximum of 0.5mm ID. This tubing is included in our connection kits.

Use of 1/32" OD tubing

1/32" OD tubing can be in combination with our Fluidic Connect Pro holder also be used, but need alternative ferrules.

The ElveFlow "Kit Fittings Starter Pack Push-in" doesn't include sleeves for use of 1/32" OD tubing. They are included in our Syringe to tube connection kit

Our Sideconnect our Fluidic Connect 4515 holders doens't support 1/32" tubing.

Elveflow uses 1/4-28 screw in connections on there reservoirs and sensors. To interface you will need Flangeless nuts 1/4-28 for 1/16" tubing, including compatible ferrules. Those nuts and ferrules are included in Elveflows "Kit Fittings Starter Pack Push-in".

This item wil look like this:

In addition you will need our connection kit. Our Connection kit includes nuts or ferrules specificilly designed for our Fluidic Connect Pro, Fluidic Connect 4515 or side connect holders. Tubing included in "Kit Fittings Starter Pack Push-in"

The 1/16"OD PTFE tubing included in the kit has a very large ID (1/32" ~0.79mm) and is from a relatively soft material, this is not so suitable for bot our Fluidic Connect Pro and Fluidic Connect 4515 holders as there's very limited wall thickness. We recommend alternative tubing, like ETFE with a maximum of 0.5mm ID. This tubing is included in our connection kits.

Use of 1/32" OD tubing

1/32" OD tubing can be in combination with our Fluidic Connect Pro holder also be used, but need alternative ferrules.

The ElveFlow "Kit Fittings Starter Pack Push-in" doesn't include sleeves for use of 1/32" OD tubing. They are included in our Syringe to tube connection kit

Our Sideconnect our Fluidic Connect 4515 holders doens't support 1/32" tubing.

I have a Fluigent pressure based pump, what connectors do I need?

Lineup

We recommend the dafault Fluigent kits (FLOW EZ™ SUPPLY KIT, FLUIWELL KIT or P-CAP KIT)

The P-cab or FLUIWELL KIT already contains 0.5m 1/16" OD FEP tubing with a ID of 500µm, when you use only limited pressures, you can try this tubing first and only order: For Fluidic Connect Pro our propriatary ferrules. For Fluidic Connect 4515 our propriatary flatbottom nuts and ferrules. For Sideconnect our propriatary ferrules. For optimal performance we recommend our complete connection kit, the FEP tubing might be a bit soft limiting the pressure rating. MFCS We recommend the dafault Fluigent kits (MFCS™-EZ HIGH/LOW PRESSURE KIT, FLUIWELL KIT or P-CAP KIT ) The P-cab or FLUIWELL KIT already contains 0.5m or 1m 1/16" OD FEP tubing with a ID of 500µm, when you use only limited pressures, you can try this tubing first and only order: For Fluidic Connect Pro our propriatary ferrules. For Fluidic Connect 4515 our propriatary flatbottom nuts and ferrules. For Sideconnect our propriatary ferrules. For optimal performance we recommend our complete connection kit, the FEP tubing might be a bit soft limiting the pressure rating.

The P-cab or FLUIWELL KIT already contains 0.5m 1/16" OD FEP tubing with a ID of 500µm, when you use only limited pressures, you can try this tubing first and only order: For Fluidic Connect Pro our propriatary ferrules. For Fluidic Connect 4515 our propriatary flatbottom nuts and ferrules. For Sideconnect our propriatary ferrules. For optimal performance we recommend our complete connection kit, the FEP tubing might be a bit soft limiting the pressure rating. MFCS We recommend the dafault Fluigent kits (MFCS™-EZ HIGH/LOW PRESSURE KIT, FLUIWELL KIT or P-CAP KIT ) The P-cab or FLUIWELL KIT already contains 0.5m or 1m 1/16" OD FEP tubing with a ID of 500µm, when you use only limited pressures, you can try this tubing first and only order: For Fluidic Connect Pro our propriatary ferrules. For Fluidic Connect 4515 our propriatary flatbottom nuts and ferrules. For Sideconnect our propriatary ferrules. For optimal performance we recommend our complete connection kit, the FEP tubing might be a bit soft limiting the pressure rating.

Publication: Implementation of a dynamic intestinal gut-on-a-chip barrier model for transport studies of lipophilic dioxin congeners.

Kulthong K, Duivenvoorde L, Mizera BZ, Rijkers D, Dam GT, Oegema G, Puzyn T, Bouwmeester H, Van Der Zande M. Implementation of a dynamic intestinal gut-on-a-chip barrier model for transport studies of lipophilic dioxin congeners. RSC Advances. 2018; 8(57): 32440-32453

Abstract

Novel microfluidic technologies allow the manufacture of in vitro organ-on-a-chip systems that hold great promise to adequately recapitulate the biophysical and functional complexity of organs found in vivo. In this study, a gut-on-a-chip model was developed aiming to study the potential cellular association and transport of food contaminants. Intestinal epithelial cells (Caco-2) were cultured on a porous polyester membrane that was tightly clamped between two glass slides to form two separate flow chambers. Glass syringes, polytetrafluoroethylene tubing and glass microfluidic chips were selected to minimize surface adsorption of the studied compounds (i.e. highly lipophilic dioxins), during the transport studies. Confocal microscopy studies revealed that, upon culturing under constant flow for 7 days, Caco-2 cells formed complete and polarized monolayers as observed after culturing for 21 days under static conditions in Transwells. We exposed Caco-2 monolayers in the chip and Transwell to a mixture of 17 dioxin congeners (7 polychlorinated dibenzo-p-dioxins and 10 polychlorinated dibenzofurans) for 24 h. Gas chromatography-high resolution mass spectrometry was used to assess the cellular association and transport of individual dioxin congeners across the Caco-2 cell monolayers. After 24 h, the amount of transported dioxin mixture was similar in both the dynamic gut-on-a-chip model and the static Transwell model. The transport of individual congeners corresponded with their number of chlorine atoms and substitution patterns as revealed by quantitative structure–property relationship modelling. These results show that the gut-on-a-chip model can be used, as well as the traditional static Transwell system, to study the cellular association and transport of lipophilic compounds like dioxins.

Publication: Microfluidic chip for culturing intestinal epithelial cell layers: Characterization and comparison of drug transport between dynamic and static models.

Kulthong K, Duivenvoorde L, Sun H, Confederat S, Wu J, Spenkelink B, de Haan L, Marin V, van der Zande M, Bouwmeester H. Microfluidic chip for culturing intestinal epithelial cell layers: Characterization and comparison of drug transport between dynamic and static models. Toxicol In Vitro. 2020 Jun;65:104815

Abstract

Dynamic flow in vitro models are currently widely explored for their applicability in drug development research. The application of gut-on-chip models in toxicology is lagging behind. Here we report the application of a gut-on-chip model for biokinetic studies and compare the observed biokinetics of reference compounds with those obtained using a conventional static in vitro model. Intestinal epithelial Caco-2 cells were cultured on a porous membrane assembled between two glass flow chambers for the dynamic model, or on a porous membrane in a Transwell model. Confocal microscopy, lucifer yellow translocation, and alkaline phosphatase activity evaluation revealed that cells cultured in the gut-on-chip model formed tight, differentiated, polarized monolayers like in the static cultures. In the dynamic gut-on-chip model the transport of the high permeability compounds antipyrine, ketoprofen and digoxin was lower (i.e. 4.2-, 2.7- and 1.9-fold respectively) compared to the transport in the static Transwell model. The transport of the low permeability compound, amoxicillin, was similar in both the dynamic and static in vitro model. The obtained transport values of the compounds are in line with the compound Biopharmaceuticals Classification System. It is concluded that the gut-on-chip provides an adequate model for transport studies of chemicals.

Publication: Transcriptome comparisons of in vitro intestinal epithelia grown under static and microfluidic gut-on-chip conditions with in vivo human epithelia.

Kulthong K, Hooiveld GJEJ, Duivenvoorde L, Miro Estruch I, Marin V, van der Zande M, Bouwmeester H. Transcriptome comparisons of in vitro intestinal epithelia grown under static and microfluidic gut-on-chip conditions with in vivo human epithelia. Sci Rep. 2021 Feb 5;11(1):3234. doi: 10.1038/s41598-021-82853-6.

Abstract

Gut-on-chip devices enable exposure of cells to a continuous flow of culture medium, inducing shear stresses and could thus better recapitulate the in vivo human intestinal environment in an in vitro epithelial model compared to static culture methods. We aimed to study if dynamic culture conditions affect the gene expression of Caco-2 cells cultured statically or dynamically in a gut-on-chip device and how these gene expression patterns compared to that of intestinal segments in vivo. For this we applied whole genome transcriptomics. Dynamic culture conditions led to a total of 5927 differentially expressed genes (3280 upregulated and 2647 downregulated genes) compared to static culture conditions. Gene set enrichment analysis revealed upregulated pathways associated with the immune system, signal transduction and cell growth and death, and downregulated pathways associated with drug metabolism, compound digestion and absorption under dynamic culture conditions. Comparison of the in vitro gene expression data with transcriptome profiles of human in vivo duodenum, jejunum, ileum and colon tissue samples showed similarities in gene expression profiles with intestinal segments. It is concluded that both the static and the dynamic gut-on-chip model are suitable to study human intestinal epithelial responses as an alternative for animal models.

Publication: Comparison of gene expression and biotransformation activity of HepaRG cells under static and dynamic culture conditions.

Duivenvoorde LPM, Louisse J, Pinckaers NET, Nguyen T, van der Zande M. Comparison of gene expression and biotransformation activity of HepaRG cells under static and dynamic culture conditions. Sci Rep. 2021 May 14;11(1):10327.

Abstract

Flow conditions have been shown to be important in improving longevity and functionality of primary hepatocytes, but the impact of flow on HepaRG cells is largely unknown. We studied the expression of genes encoding CYP enzymes and transporter proteins and CYP1 and CYP3A4 activity during 8 weeks of culture in HepaRG cells cultured under static conditions (conventional 24-/96-well plate culture with common bicarbonate/CO2 buffering) and under flow conditions in an organ-on-chip (OOC) device. Since the OOC-device is a closed system, bicarbonate/CO2 buffering was not possible, requiring application of another buffering agent, such as HEPES. In order to disentangle the effects of HEPES from the effects of flow, we also applied HEPES-supplemented medium in static cultures and studied gene expression and CYP activity. We found that cells cultured under flow conditions in the OOC-device, as well as cells cultured under static conditions with HEPES-supplemented medium, showed more stable gene expression levels. Furthermore, only cells cultured in the OOC-device showed relatively high baseline CYP1 activity, and their gene expression levels of selected CYPs and transporters were most similar to gene expression levels in human primary hepatocytes. However, there was a decrease in baseline CYP3A4 activity under flow conditions compared to HepaRG cells cultured under static conditions. Altogether, the present study shows that HepaRG cells cultured in the OOC-device were more stable than in static cultures, being a promising in vitro model to study hepatoxicity of chemicals upon chronic exposure.

What are the dimension of the available view window using the resealable / OOC chip holder?

The view window on the bottom of the resealable/OOC chip holder has the dimensions as found in the picture below:

Would you like to submit a question? Please login first.

We found other products you might like!

-

OOC setup (no pumps included)

OOC setup (no pumps included)From €3,968.00

To €7,781.00