Enhanced oil recovery (EOR) chip - topconnect

per pack of 3

Enhanced oil recovery chips can be used to verify calculation models, providing an optical clear surrogate rock. Known geometrical conditions and optical clear chips create optimal conditions to study physical processes that normally occur inside rock formations.

Our Enhanced Oil Recovery chips mimick porous medium and are often used for veryfing and development of computer simulation models, development of elmulsification chemcials or other chemicals that enhance oil production, microbiological enhanced oil production, research on effects of gas injections in oil fields.

The chips are available in three designs as listed below and can be supplied with or without a hydrophobic coating. By default glass behaves hydrophilic. The optional coating is applied on a best effort base, it is possible that some areas where geometries are not interconnected will stay uncoated.

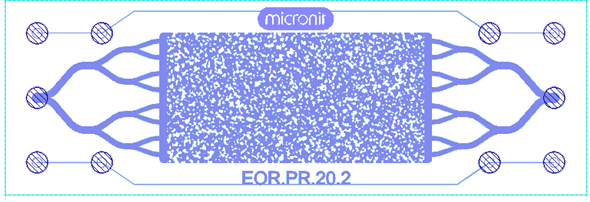

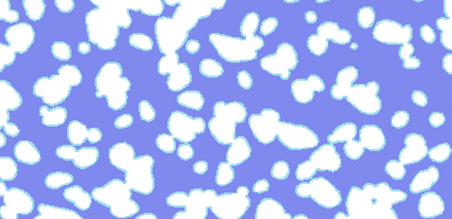

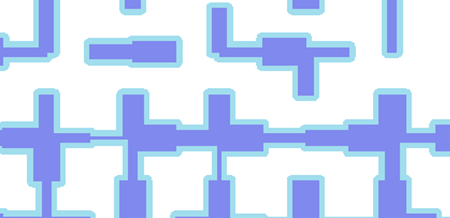

Physical rock network

This chip is designed by randomly placing rock shaped structures on the chip to resemble the shape that is obtained by cutting rock as accurately as possible. This random structure results in throats and channels between the rock structures. This method of random placement does not give information on throat size distribution. For simulation purposes, the mask (2D) design is available on request. However, experience has taught us that the complexity of this structure makes it challenging to run computer simulations on.

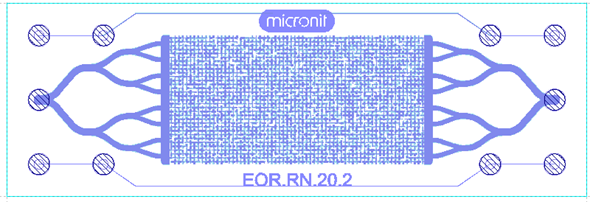

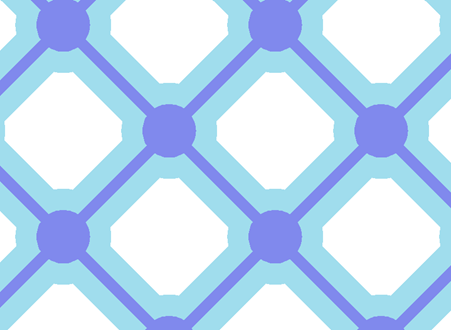

Random network

Random network porous structure chip, often used for Chemical Enhanced Oil Recovery (CEOR) and Microbial Enhanced Oil Recovery (MEOR) experiments.

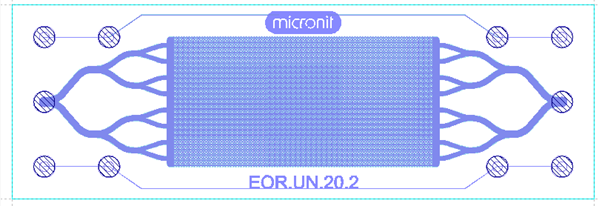

Uniform network

A systematically organized and well-defined rock-pore structure of equally sized pores and channels.

| Unit of measurement | pack of 3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alternative item references | EOR.PR.20.2, 02976, 01954; EOR.UN.20.2, 02978, 02198; EOR.RN.20.2, 02977, 02199 | ||||||||

| Interface type | Topconnect | ||||||||

| Chip thickness | 1800µm | ||||||||

| Chip material | Borosilicate glass | ||||||||

| Number of inlets | 1 | ||||||||

| Number of outlets | 1 | ||||||||

| Supply format & dimensions | Supplied in black polymer cardtridge (polypropylene). The glass element has a size of 45x15mm. | ||||||||

| Permeability (Darcy) |

|

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| EOR information | Additional information on the Uniform, Random and Physical rock network structures. | 257.8 KB | Download | |

| 11002978 / 11002198 / EOR.UN.20.2 - Drawing | Drawing for the EOR porous medium chip with Uniform Pore Network. Items 11002978 and 11002198 | 378.2 KB | Download | |

| 11002977 / 11002199 / EOR.RN.20.2 - Drawing | Drawing for the EOR porous medium chip with Random Pore Network. Items 11002977 and 11002199 | 123.7 KB | Download | |

| EOR.PR.20.2 - Drawing | Drawing for the EOR porous medium chip with a Physical Rock Network. Items 02976 and 01954 | 139.5 KB | Download | |

| Permeability determination of catalogue chips | This documents describes how permeability values of EOR chips with a Uniform Network, Random Network and Physical Rock network are determent. | 983.2 KB | Download |