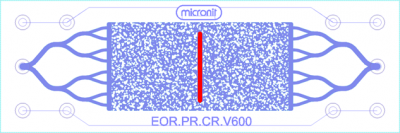

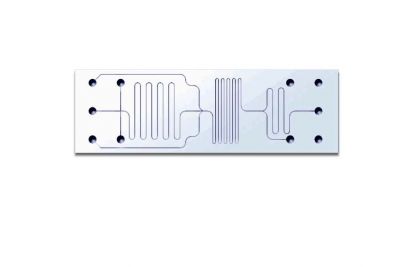

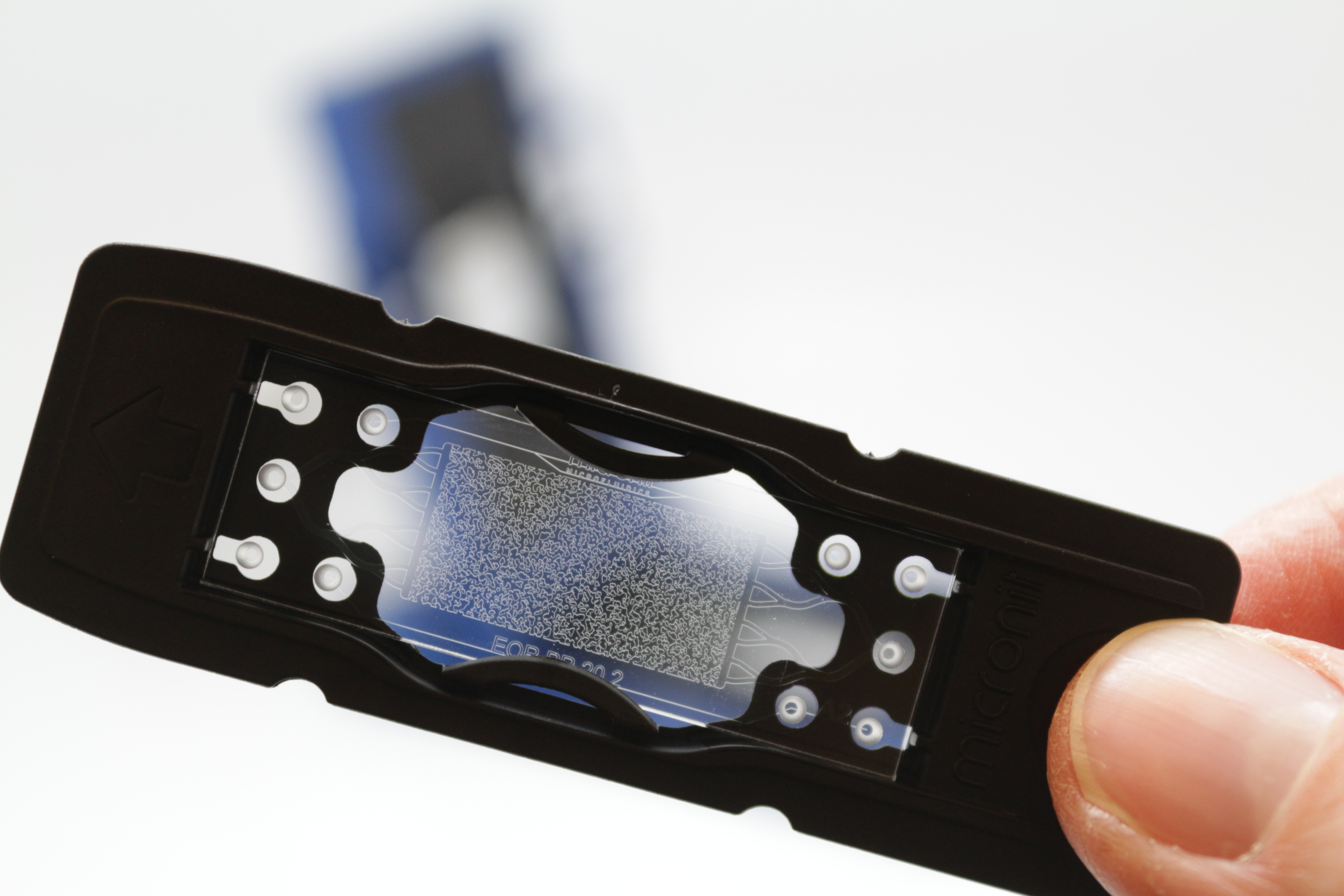

Enhanced oil recovery chips

To study thermal, chemical and microbial Enhanced Oil Recovery (EOR) and the effectiveness of these technologies, the most accurate way is to use a physical rock. The use of ‘real’ rocks has several major drawbacks, however. Therefore, Micronit has developed three types of Enhanced Oil Recovery chips in collaboration with several leading industrial partners. This way, experiments can be conducted on surrogate rocks, using lab-on-a-chip technology. These chips can be used for several types of research concerning Enhanced Oil Recovery,...

Read More

To study thermal, chemical and microbial Enhanced Oil Recovery (EOR) and the effectiveness of these technologies, the most accurate way is to use a physical rock. The use of ‘real’ rocks has several major drawbacks, however. Therefore, Micronit has developed three types of Enhanced Oil Recovery chips in collaboration with several leading industrial partners. This way, experiments can be conducted on surrogate rocks, using lab-on-a-chip technology. These chips can be used for several types of research concerning Enhanced Oil Recovery, whether it is for reservoir engineering or environmental issues. Three different types of EOR chips have been developed, each designed to mimic a different rock structure. The chips are available with either a random, a uniform or a physical rock structure network.

Read Less-

Enhanced oil recovery (EOR) setup - high pressure (no pumps included)

Enhanced oil recovery (EOR) setup - high pressure (no pumps included)From €2,025.00

To €10,593.00

per Bundle -

Enhanced oil recovery (EOR) setup - low pressure (no pumps included)

Enhanced oil recovery (EOR) setup - low pressure (no pumps included)From €2,410.00

To €10,671.00

per Bundle