shopping_basket

Droplet generation setup - topconnect (no pumps included)

This setup does not include pumps. For droplet generation, we recommend pressure based pumps to ensure an optimal experience. Pressure based pumps use stabilized pressure to push liquid out of a reservoir. Syringe pumps can generate a step wise movement in pressure release. This can result in pulsations, that cause instability in droplet generation. There are some high-end syringe pumps on the market that might overcome this issue, but we have limited experience with such pumps. For use in combination with high-end syringe pumps our might be a useful addition.

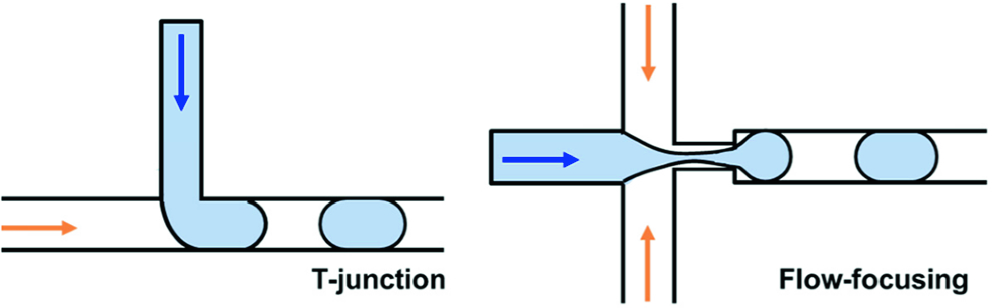

Droplet generation chips are available in the following types:

- Focused Flow

- T-shaped

- Parallel

Focused flow droplet generators are available in the following configurations:

| SKU | Nozzle size | Coating | Use for | Recommended droplet size (reference liquids) |

| 00935 | 10µm | Non - Hydrophilic | Oil-in-water droplets | 9µm< droplets <20µm |

| 01341 | Hydrophobic | Water-in-oil droplets | ||

| 02137 (Beta product) | 20µm | Non - Hydrophilic | Oil-in-water droplets | 15µm< droplets <30µm |

| Hydrophobic | Water-in-oil droplets | |||

| 00877 | 50µm | Non - Hydrophilic | Oil-in-water droplets | 40µm< droplets <90µm |

| 01366 | Hydrophobic | Water-in-oil droplets | ||

| 00580 | 75µm | Non - Hydrophilic | Oil-in-water droplets | 65µm< droplets <140µm |

| 00970 | Hydrophobic | Water-in-oil droplets |

T-shaped droplet generators are available in the following configurations:

| SKU | Coating | Use for | Channel width | Channel height |

| FC_TSDG.2_PACK | Non - Hydrophilic | Oil-in-water droplets | 100µm | 20µm |

| FC_TSDG.C.2_PACK | Hydrophobic | Water-in-oil droplets | 100µm | 20µm |

Parallel droplet generators combine multiple focused flow droplet generators in parallel on a single chip with a shared inlet and outlet for increased production rates. They are available in the following configurations:

| SKU | Nozzle size | Number of junctions | Coating | Use for | Recommended droplet size (reference liquids) |

| 00923 | 75µm | 8 lanes | Non - Hydrophilic | Oil-in-water droplets | 65µm<droplets <140µm |

| 02067 | Hydrophobic | Water-in-oil droplets |

| Unit of measurement | Bundle |

|---|---|

| Application | Droplet generation |

| Holder concept | Fluidic Connect Pro |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| Flow rate instructions | 303.6 KB | Download | ||

| Surface wetting properties | 220.3 KB | Download | ||

| How to prevent clogging | 153 KB | Download | ||

| Using the right surfactants | 168.8 KB | Download | ||

| Droplet Generator Guide | 617 KB | Download | ||

| TSDG.2 - T-shaped droplet generator | 67.3 KB | Download | ||

| DGFF.P8.75 - Parallel droplet generator 75µm, 8 junctions -Drawing | 458.8 KB | Download | ||

| DGFF.50 - Drawing | Drawing for 50µm Topconnect Focused Flow Droplet Generator. Items 01366 and 00877. | 179.6 KB | Download | |

| DGFF.75 - Drawing | Drawing for 75µm Topconnect Focused Flow Droplet Generator. Items 00970 and 00580. | 193.6 KB | Download | |

| DGFF.10 - Drawing | Drawing for 10µm Topconnect Focused Flow Droplet Generator. Items 01341 and 00935. | 159.2 KB | Download | |

| Fluidic Connect Pro - Droplet quick start guide | A manual how to assemble the holder for use with a droplet generator. | 5.8 MB | Download |

Customer Questions