Product Request Form

With 20+ years of experience in the broader microfluidics field, Micronit is a steady development partner. And our experience is available to you!

We offer our customers a full design-to-manufacturing service. Delivering high-end innovative products is our core business. Our ambitions are primarily in the field of life sciences and health applications and our facilities are ISO 9001 and ISO 13485 certified.

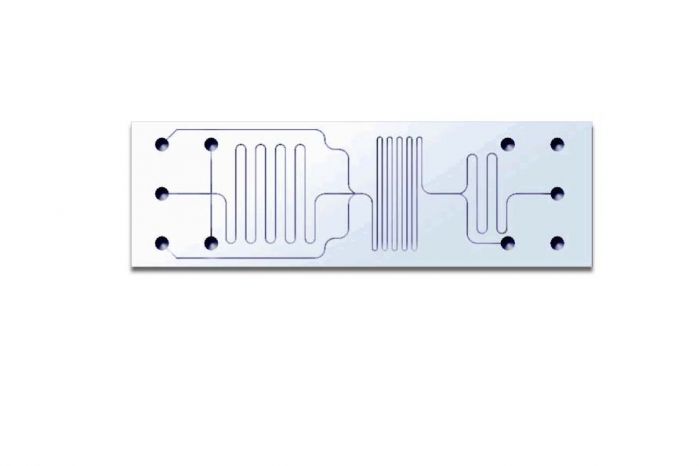

We team up with our clients in an 'idea-to-manufacturing' process. We not only design ground-breaking chip layouts, but also keep a sharp eye on the manufacturability of the product. Making the right design choices from the very beginning, prevents delays in later stages of the process.

Interested in a partnership in the development of your product? Go to Product Development.

If you already have a clear view on the product you need, you can fill in the Product Request Form below. Please give us a comprehensive view on the type of use and layout of the product, preferably with your initial drawings.

We'll get back to you asap to further discuss your request!

To remove particulate matter from your chip, a water bath with ultrasonic agitation can be used, preferably while flushing a watery solution through the channels.

Glass microchips can be heated (e.g. 400°C) causing any organic material on the glass surface to degrade. Try to use lower temperatures first because burning the content could make it stick. Make sure you only heat the glass chip and not the plastic parts around it.

Concentrated sulfuric acid works well to dissolve organic material, such as fibres, that are difficult to remove with alkaline solutions. Always keep in mind that you are working with extremely corrosive material. Please note that this instruction is focused on the chip itself, PEEK elements like connectors are not so compatible with strong sulforic acid.

Please note that chips that were coated by Micronit have different guidelines for cleaning!

The channel shape. The channel height and width.

For wet etching its important to consider that channel height and minimal channel width are related.

{minimal channel width} = 2 * {etch depth} + {initial mask opening, typcial 5-10µm}

Larger aspect ratios (relation between channel depth and width) are possible using dry etching. For this, a glass/silicon combination is most common. Choice of material. For instance, fused silica is a good option when UV light is used. Schott D263 bio can be a good alternative for some specific fluorescent labels. Surface flatness. We can provide ultra flat surfaces.