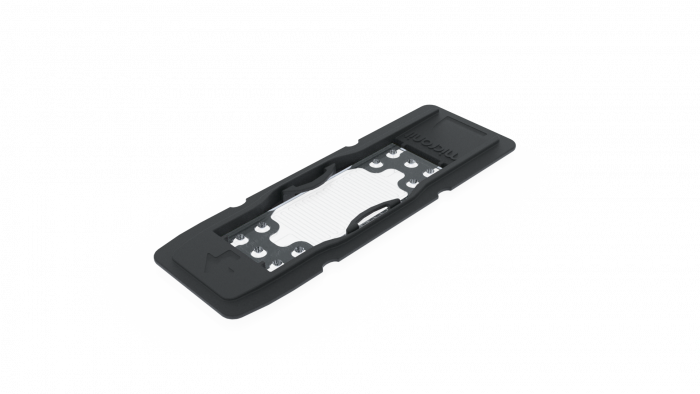

Serpentine channel / Microreactor, 45x140µm, 350mm length

SKU

11003040

Availability:

In stock

€384.00

per pack of 3

Flow cell with a serpentine channel with a length of 350mm. Channel width: 145µm, channel height: 45µm.

The chip has a 175µm thick bottom and is manufactured from D263Bio glass.

Application possibilities

This product is designed for observation purposes and offers sublime optical performance in combination with microscopy. This allows high resolution imaging.

Unique selling points

- For cell up to 40µm in diameter

- 350mm of observation length, 28 meanders of 11.90mm

- Thin bottom, 175µm channel bottom thickness (1.5 coverslip)

- Extremely low autofluorescence, highly suitable for use with fluorescent markers.

- Manufactured from high-end glass, channels are extremely smooth and fully transparent.

- The channel contain 3 inlets, unused inlets can be blocked using .

Key features of the product are:

| SKU | Number of inlets | Number of outlets | Channel width | Flat channel area width | Channel height | Glass height on top of channel | Glass height below channel | Chip height |

| 11003040 | 3 | 1 | 140µm | 50µm | 45µm | 1100µm | 175µm | 1275µm |

Interfacing

This product is compatible with our .

Because of the limited chip thickness it’s necessary to use the metal strips included with the holder, see here for more information

| Unit of measurement | pack of 3 |

|---|---|

| Interface type | Topconnect |

| Chip material | Borosilicate glass |

| Number of inlets | 3 |

| Number of outlets | 1 |

| max. cell height for optimal observation | 40µm |

| Internal volume | Internal volume 1.86µl |

| Coating | No coating (hydrophilic) |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| 11003040 - Drawing | Serpentine 45x140µm, 350mm, TB | 76.9 KB | Download | |

| 11003033 - Drawing | Serpentine 140x250µm, 500mm | 94.2 KB | Download |

Customer Questions

We found other products you might like!